Precision Stamper Manufacturing for Flawless Playback

Vinyl records show even the slightest variation during playback. During our stamper process, your record undergoes a meticulous and proven process designed to guarantee the highest standards of quality and precision before it reaches the pressing phase. From the initial creation of the stamper to its polishing, precise centering, exact trimming and final forming, we carefully take your master through every step to prepare it for vinyl pressing.

In-House Harmony

Eliminate delays and potential errors associated with transporting lacquers from cutting houses to manufacturing locations. With our full suite of vinyl solutions all offered in house, we guarantee efficiency and precision at every stage, from lacquer cutting to stamper manufacturing to pressing, and beyond.

OUR PROCESS

The Foundation of Flawless Pressing

Once we receive the lacquer masters for each side of your record, we’ll process them for the next step. Each is sprayed with liquid silver and nickel plating to form the stampers that will be used to press the actual record. We offer two plating options – a 2 step and 3 step process. Most of our work includes the 3-step process, which ensures the highest quality sound.

The multi-step journey of a stamper from creation to readiness requires meticulous attention to detail:

Polishing

Our skilled technicians hand-sand each stamper to eliminate any imperfections that could compromise the record’s quality, while a soft, velvet pad protects the grooved surface, ensuring the integrity of your sound is preserved.

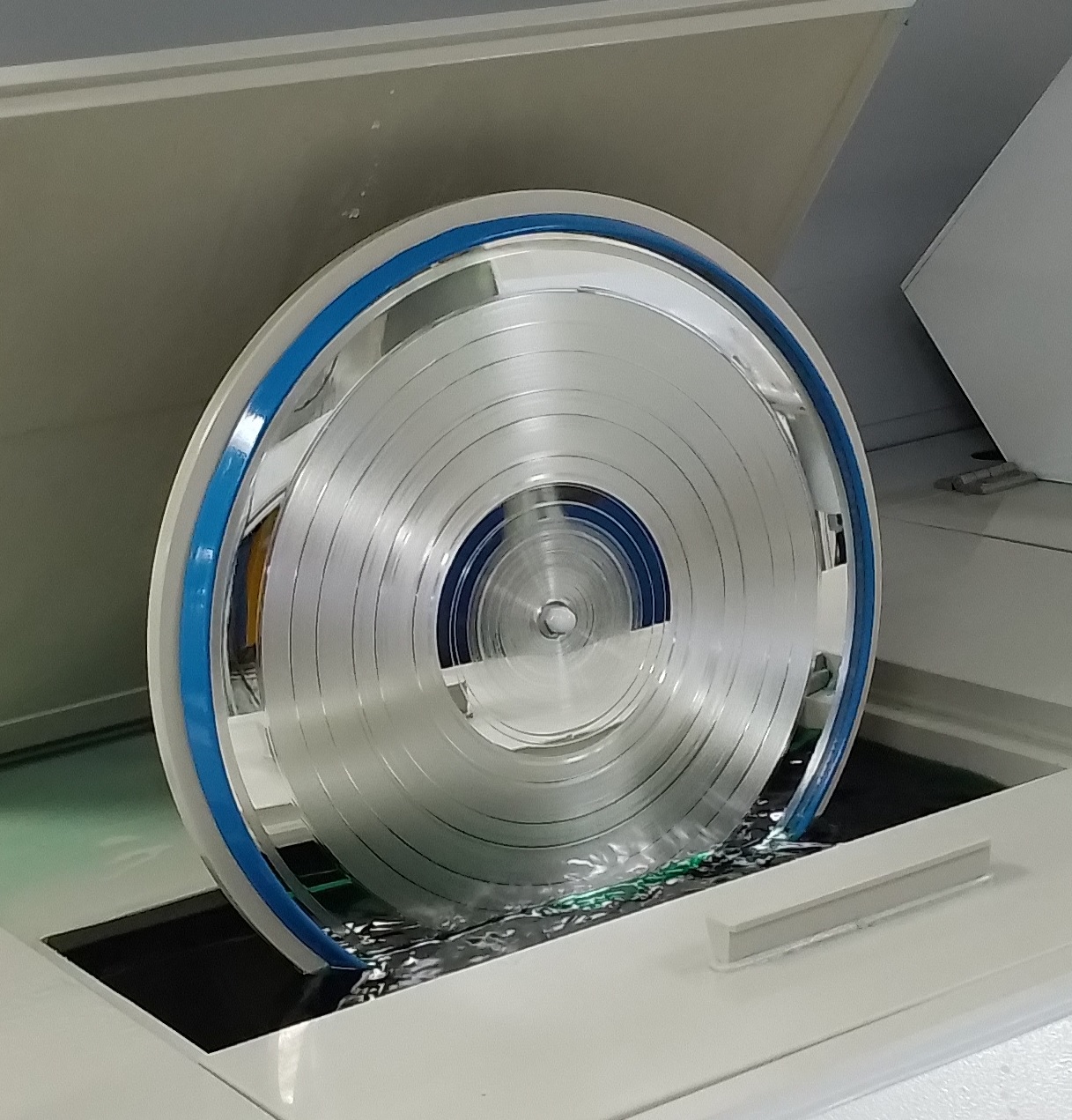

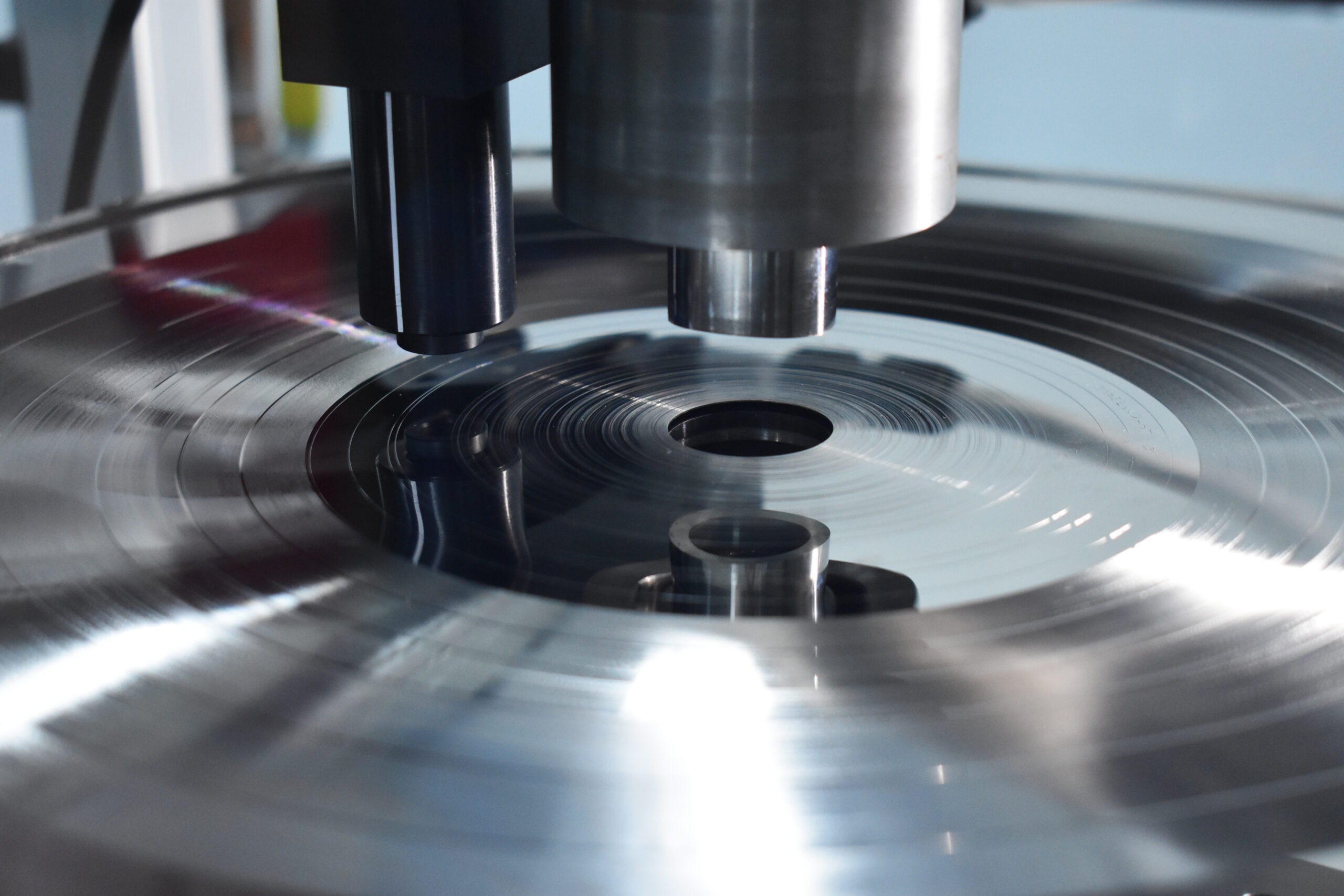

Centering

This ensures the stamper’s central hole aligns perfectly with the spiral groove. Using a rotating wheel device and a magnified view, our operators carefully adjust the stamper’s position, guaranteeing the groove’s center matches the physical center of the record. This precise process ensures a balanced and true sound, free from distortion.

Trimming & Forming

Once the stamper has been polished and centered, it will undergo a trimming and forming process to prepare it to snugly fit the stamping mold and ensure a secure clamping during pressing. This detailed preparation of stampers is more than a process; it’s our promise of quality.

Vantiva is Your Trusted Partner in Vinyl Solutions

Our team of pros is dedicated to perfection at every stage of the vinyl production process. Guiding your audio from the initial cut to the final press, we ensure every record not only plays flawlessly but captures the full spectrum of the sound you intended.

For an outcome that impresses from the first note to the last, Vantiva is your premier choice.